35

of 250 feet to accommodate larger steamships bearing bigger

cargoes. At about six million cubic yards, the sediment removed

from the floor of Baltimore’s harbor was twice the volume of

Egypt’s Great Pyramid.

Sediment arouses strong sentiment on the waterfront. Back

in Baltimore’s dark ages, a navigable harbor was so vital that

town officials deemed it a crime to throw dirt or sand into the

Patapsco, punishable by a fine of five British pounds — a whop-

ping one month’s salary in the early 18th century. The ongoing

need for harbor dredging, as well as control over the placement

of dredged material, remain problematic issues which still vex

Maryland’s maritime community in the early 21st century, and

will be closely monitored.

The second key development, a “differential” imposed by Inter-

state Commerce Commission regulators on railroad companies,

instituted a freight system in which the cost of moving goods was

made proportional to the overland distance the goods moved: For

a Chicago merchant, it suddenly became cheaper to ship goods

through Baltimore’s port as opposed to New York, reflecting the

fact that Baltimore is 90 miles closer to Chicago.

The differential — whose groundwork was laid down by John

Work Garrett and Enoch Pratt, a major investor in the B&O until

his death in 1873 — helped equalize the natural gifts enjoyed by

New York’s port, whose vast harbor adjacent to the sea, the Hudson

River and an extensive railroad network was a strategic advantage

over rival ports.

Canton was emerging as the Port’s heavy industrial arm.

O’Donnell’s 3,000-acre estate, which included all the waterfront pro-

perty from Fell’s Point to Lazaretto Point opposite Fort McHenry,

was developed piecemeal by industries enticed by the prospects

of partnering with some aspect of the Port’s lines of business.

Canton’s commercial orientation was distinctly maritime —

refineries and smelters turning out copper products that resist the

corrosive effects of salt water, and iron mills and foundries. The

Baltimore Copper Company was among the first to locate there;

with Enoch Pratt and Johns Hopkins on board as lead investors,

it was America’s largest copper refinery before being recast as

American Smelting and Refining Company. Most ships then

manufactured in America were sheathed in copper, which

accounts for the longevity of the

Constellation

in today’s Inner

Harbor. In 1848, the Booz Shipyard was established on Harris

Creek at the foot of Kenwood Avenue.

Horace Abbott’s Canton Iron Works ( first started by Peter

Cooper), capable of manufacturing the largest rolled plate in the

United States by 1850, built armor plates for the first iron battle-

ship, the

Monitor

. The Patapsco Bridge & Iron Works gained a

national reputation for its engineering feats, and built many of

the bridges spanning the Jones Falls.

Railroad and steamboat

connections to the Port profited

watermen and helped open up Chestertown, Centreville, Oxford,

Cambridge, Crisfield and Berlin on the Delmarva Peninsula by

injecting commerce and capital into the regional economy.

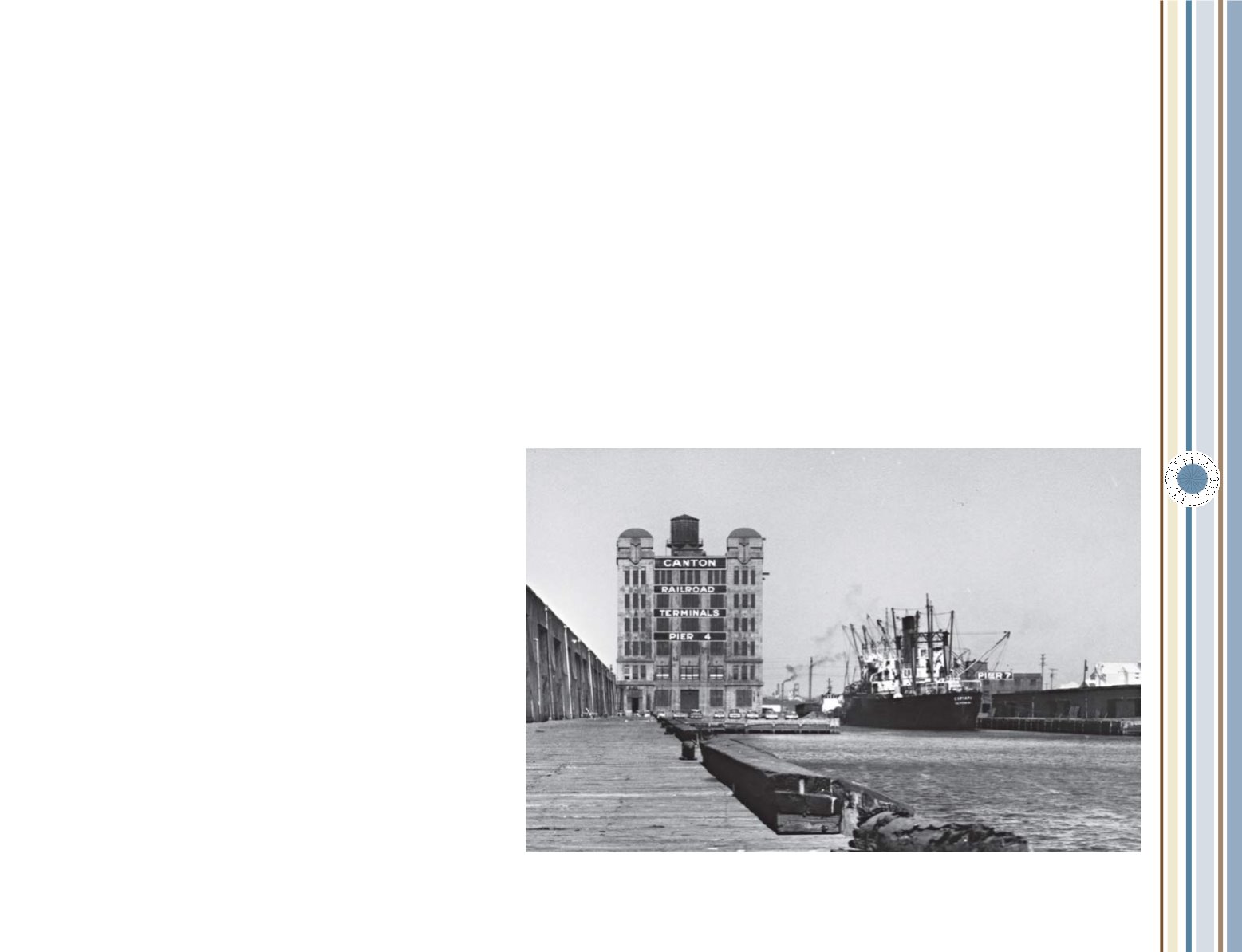

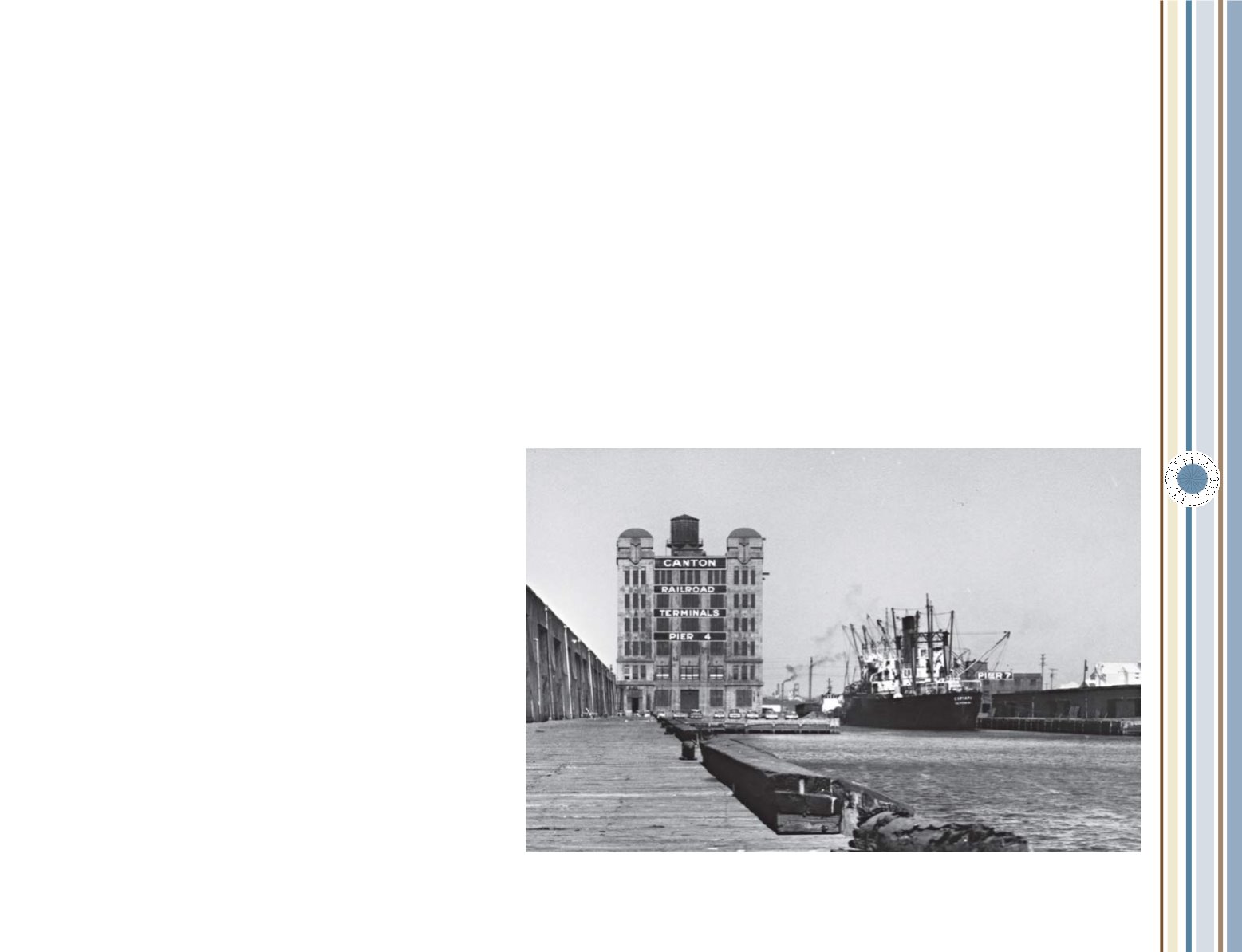

The Canton Company

completed the Canton Railroad

in 1914, providing direct

connections between industry

and three major railroads:

the Baltimore & Ohio, the

Pennsylvania and theWestern

Maryland lines. Today, the

Canton Railroad’s brightly

painted engines continue to

provide short line service for

CSX and Norfolk Southern.